Learn more about waterjet cutting

Water cutting, is the most universal and flexible cutting method available.

Using the same technology, abrasive or non-abrasive, you can cut all materials, thin or thick, hard or soft, with high precision, minimum material waste and without any heat affect. Water cutting usually reduces the number of operations required for completing products.

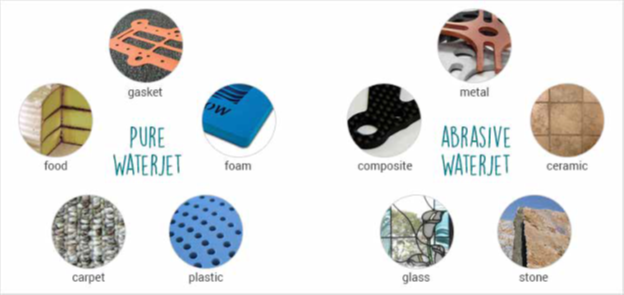

Pure water cutting is mainly used for soft material and non-metals: Gaskets, sandwich material, polymer, rubber...

Abrasive water cutting is used for hard or brittle materials: stainless steel, titanium, aluminium, brass, glass, stone, composites...

Waterjet Basics

The waterjet process provides many unique capabilities and advantages that can prove effective in your ongoing battle to reduce costs, increase efficiencies, and maintain quality in your shop. The more you know about waterjet technology, the better you’ll be able to understand the benefits it can bring to your operation.

Waterjets entered the manufacturing scene in the early 1970’s cutting soft materials like cardboard. In the mid 1980’s, the abrasive waterjet was invented by a team led by Dr. Mohamed Hashish at Flow, expanding the capabilities of the tool to cut hard materials. The basic technology is simple, yet complicated at the same time.

At its most basic, water flows from a pump, through plumbing and out a cutting head. It’s simple to explain, operate, and maintain. The process, however, incorporates extremely complex materials, technology, and design.

Waterjet pumps today are usually rated to pressures between 60,000 and 94,000 psi (~4100 to 6400 bar). To put it in perspective, your home water pressure is about 60 pounds per square inch (~4 bar) and a fire hose delivers about 200 psi (~14 bar). In the waterjet machine tool, the pressurized water safely runs to the cutting head through ultrahigh-pressure plumbing comprised of T’s, elbows, swivels, and flexible stainless steel lines with diameters from ¼” OD to 9/16” OD (6.35 to 14.3 mm outside diameter). At the cutting head, a high speed air actuated On/Off Valve allows the water to pass through the jewel orifice creating a supersonic waterjet stream.

Despite the high psi, waterjets don’t actually cut with pressure but instead rely on velocity. The water pressure is exchanged for velocity when the water passes out of the cutting head’s orifice. The higher the pressure, the higher the stream velocity. At 60 psi, tap water out of a faucet is traveling 64 miles per hour (103 km/hr). At 94,000 psi, the waterjet is traveling nearly 2,500 miles per hour (4,000 km/hr) -- more than three times the speed of sound.

Pure Waterjet

Pure waterjet is the original waterjet cutting method. It features a thin stream (.004 to .010 diameter), extremely detailed geometry, fast cutting speed, and is able to run 24 hours per day. The largest uses for pure waterjet cutting today involve soft materials like gasket, foam, disposable diapers, tissue paper, plastic, carpet, and food.

Abrasive Waterjet

An abrasive waterjet adds a garnet abrasive fed into the cutting head, mixed with the pure waterjet stream, and used to cut hard materials like metal, ceramic, stone, glass and composite.

Adding abrasive to the supersonic waterjet stream increases the cutting power a thousand times. To avoid passing mud through the pump, the abrasive is kept clean and dry in a bulk transfer hopper and added to the cutting head at the last second. Once in the cutting head, the abrasive is accelerated by the water and shot out of the mixing tube like a bullet out of a rifle.

An abrasive waterjet, therefore, is a slurry of water, abrasive, and a little air. The process uses roughly one gallon per minute of water (3.8 l/min) and one pound per minute of abrasive (0.45 kg/ min.). Abrasive grit sizes range from 50 to 220 mesh garnet, but the most common is 80 mesh.